What Is Solar Grounding?

Solar grounding connects the metal components and wiring within your solar panels to the ground.

Creating a connection between your system and the earth establishes a safe pathway for any fault currents to flow safely away from people, the solar system, and any vehicles or equipment in the area.

This is vital because no one can predict when insulation might fail or when lightning may strike.

Purposes of Solar Grounding

There are three primary purposes for grounding:

- Grounding protects against potentially lethal voltage buildup by creating a low-resistance pathway for any fault currents. Thus, it is imperative to protect personnel and others against electric shocks.

- Grounding effectively diverts lightning away from your system into the earth. This helps protect the solar panel and minimizes any potential damage.

- Grounding diverts any voltage into the ground and helps ensure that short circuit and insulation failures don’t destroy your system.

How Solar Grounding Works

To ground your system, you need to install a ground rod. This rod is driven directly into the earth, typically around 8 feet deep.

One end of the rod is connected to a grounding wire and conductors that can transfer the voltage away from the solar panels. The wire is connected to the frames, mounting structures, and conduit on the other end.

DynoBond Solar Grounding

At DynoRaxx, our DynoBond solution is designed to ensure your solar installation is properly grounded and protected.

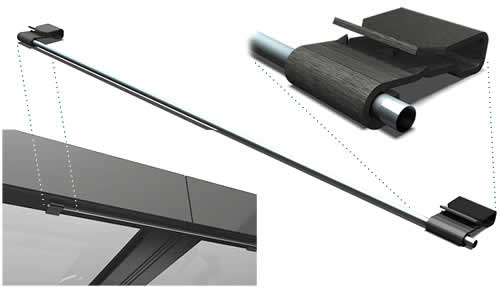

Our patent-pending grounding solution consists of specialized bonding jumpers and cables that directly establish an uninterrupted path from your solar system to your grounding rod.

Attaching these jumpers to your system is as simple as clipping them to the solar panel’s frame, at which point the frame becomes the primary conductor.

It’s fast, simple, and creates durable protection that ensures the safety and longevity of your solar installations. When you choose our UL 467 and UL 2703 compliant systems, you’ll enjoy easy installation and dependable longevity.

DynoBond vs. Traditional Grounding Wires

Traditionally, each solar panel needed an individual grounding lug connected to a grounding wire running throughout the array.

DynoBond reduces the number of grounding wires by electrically linking modules together, meaning fewer individual ground connections are needed.

How DynoBond Supports Solar Grounding Compliance

Many solar panel racking systems are UL 2703-certified, meaning they have integrated grounding features. DynoBond can serve as a certified bonding method when racking and modules are not inherently bonded.

Some solar installations require additional grounding measures beyond racking bonding, and DynoBond helps meet NEC 690.43 grounding and bonding requirements.

Choose DynoRaxx for Your Solar Mounting Needs

Since 2007, the team at DynoRaxx has provided the exceptional solutions solar companies depend on.

Our no-tool installation solutions will allow you to install more systems faster, safer, and better than your competitors!

When you want high-quality products made in the U.S. to support your solar installation, contact our team at DynoRaxx today! We ship globally.